Newgreen (Zhejiang) Intelligent Co., LTD., relying on the efficient R&D team and the tireless pursuit of technology, researches and develops the high-speed intelligent vertical seamer machine after more than a year. It obtained a number of national invention patents and utility model patents and appearance patents, at one fell fell to break the foreign monopoly for many years of seaming technology.

The machine can be equipped with two sets of seaming wheel feed mechanism to realize the seamless connection between the different thickness of the drum. Drive mechanism abandons the traditional hydraulic and pneumatic devices, using servo motor instead of flywheel and clutch, CAM feed system with independent motor drive, which greatly improves the efficiency, accuracy and saves energy saving and protects environment. All adjustment devices have been electric and intelligent.

1. Device configuration

Machine equipped with:

(1) One set of seaming wheels with a thickness of 0.7/0.8mm (one for the first seaming wheel and one for the second seaming wheel);

(2) One set of seaming wheels with a thickness of 0.9/1mm (one for the first seaming wheel and one for the second seaming wheel);

(3) One set of seaming wheels with a thickness of 1.2mm (one for the first seaming wheel and one for the second seaming wheel);

(4) Automatic oil injection lubrication device for seamer machine.

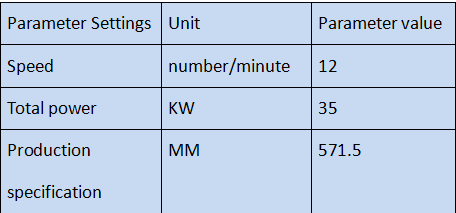

2. Technical parameters

3. Equipment advantages

a. The motor starts and stops to control the rotation of the seaming plate to avoid excessive seaming of the lid and scratches on the surface due to wear and producing defective parts.

b. A group of sliding block quick-assembly components is arranged between the bracket of the seaming device and its body, which not only ensures the stability of the body, but also facilitates disassembly and assembly, so as to facilitate the maintenance of the seaming device.

c. Automatic feed adjustment is optional for the seamer machine to simplify the adjustment process and reduce the difficulty of the process.

d, With integrated drum weld identification, lid flange positioning function, the efficient seaming can be realized.

e, With CAM independent motor drive, accurate control can be realized.

f, The upper pressure plate is driven by servo motor, with pressure sensor,giving continuous pressure to the drum, to ensure the seven-layer seaming process.

The perfect pursuit of technology and equipment has driven the Newgreen engineer to be committed to equipment debugging and R&D.The eventually developed vertical smart seamer machine realized the intelligence vertical processing of the seaming drum, meeting a series equipment of real-time, on-line, non-contact, high speed, high precision. The system runs stably, monitoring function is perfect, which greatly improve the automation and intelligence of drum production line. It has opened up a precedent in the field of intelligent drum making.

4. Pictures of equipment and effect drawing of seaming

5. Our vertical seamer machine has been patented